Category

Custom OEM ODM Corner Brace for Appliance

Description 1.What are our advantages over others?a). Merid Machinery is an ISO certificated custom metal parts manufact

Basic Info.

| Model NO. | Merd-6147 |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customized | Customized |

| Standard or Non-Stardard | Non-Standard/Customized |

| Transport | by Sea, Air or Express |

| Export Markets | Global |

| Color | as Per Clients′ Requirements |

| Certificate | ISO SGS as Customized |

| MOQ | Sample Order Is Acceptable |

| Inspection | 100% Before Shipment |

| Process Method | Blanking, Punching, Bending, Forming |

| Product Name | Steel Sheet Thread |

| Feature | Durable |

| Lead Time | 15-45days |

| Supply Ability | 50000 Piece/Pieces Per Month |

| Transport Package | Wooden or Others |

| Specification | Customized |

| Trademark | Merid |

| Origin | Qingdao, China |

| HS Code | 7308900000 |

| Production Capacity | 50000pieces/Month |

Product Description

Description| Manufacturer | Merid Machinery with advanced technology,professional skill and experienced technicians to fit our customers requirements. |

| Material available | Carbon steel , Stainless steel , spring steel , Bronze , brass , copper alloy , aluminum alloy , tinplate , nickel silver , customized material |

| Process available | Stamping ,welding ,forging ,die casting , precision casting , turning , milling , drilling , grinding etc |

| Specification | OEM , ODM according to drawings or samples |

| Surface treatment | self-color, galvanized , polishing , Zinc, powder coating , painting , nickle , chrome , polish , e-coating , brush , wire drawing , plating etc |

| Tolerance | Stamping parts: 0.01-0.1mm, CNC machining parts: 0.1-0.002mm |

| Design | used the advanced mould design software |

| Price term | FOB Qingdao T/T |

| Delivery | 25-60 days based on the different products |

| Package | Poly , carton , wooden case or as required |

| Application | automotive parts , railroad parts ,medical parts , marine parts , lighting parts , valve parts , architectural parts ,construction parts, sport accessory and furniture parts etc |

1.What are our advantages over others?a). Merid Machinery is an ISO certificated custom metal parts manufacturer,We have our own factory, quality can be controlled seriously and price is very competitive. Stamping, Machining, Welding, Die casting and Surface treatment equipment are equipped for providing you our best service and solutions.b). Nearly 30 years experience.c). On-time delivery.e). Strict Quality Control System: 100% inspection before the shipment.

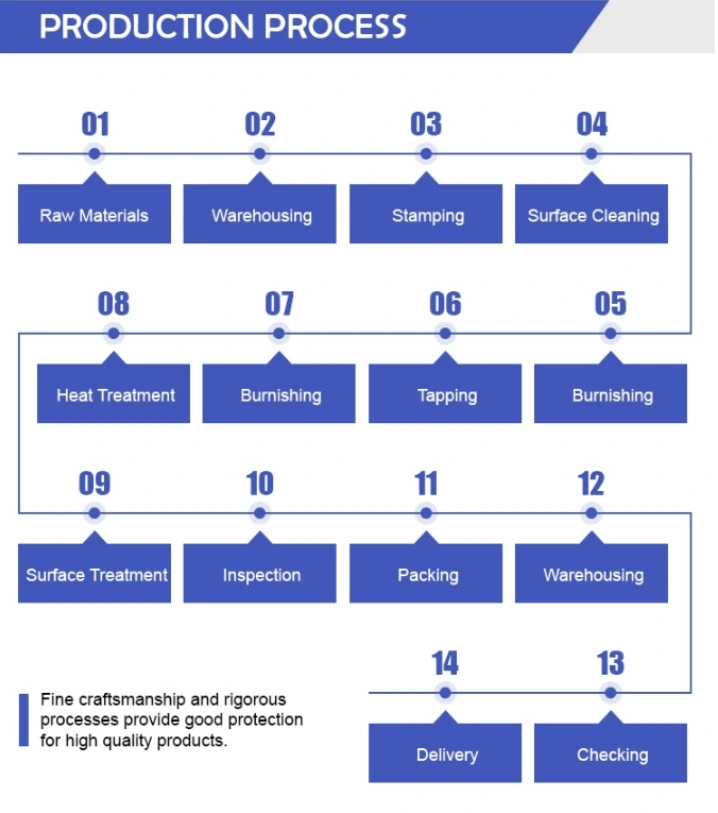

2.What equipment do you own?a). Punch Press: 16T-500T.b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.c).Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).d). Die casting: 80T-500T.e).Surface treatment: Shot blasting facility, Polishing, Deburring.3.What finishes can you provide?The finishes which we could provide is powder coating, painting, galvanizing, plating, baked enamel,polishing, anodizing finish, and other plating finishes.4.How can you guarantee the quality?Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.Carbon Steel Metal Stamping Protection Part for Machine Home Appliance 5.What is your terms of payment ?30% paid to start the mass production and 70% balance paid at the sight of copy of B/L.6.Do you offer samples?Yes, some samples can be provided for free,and some

Samples need to pay mold fee .

7. What will you do for after-service?When our metal parts apply to your products, we will follow-up and await for your feedback.If need any help of the assembly or other matters, our professional engineer will give you a best solutions.